2012

Established

Main technical parameters:

|

Model |

BW4N12 |

BW6N30 |

|

The number of capping head |

4 |

6 |

|

The number of filling bead |

12 |

30 |

|

Can Height |

50~160mm |

50~160mm(Special specification is availabe) |

|

Can Diameter |

52~99mm |

52~99mm |

|

Filling capacity |

70~850g(At present three cylinder diameter) |

70~850g(At present three cylinder diameter) |

|

Production capacity |

80~200{c/min}(And the filling quantity and so on) |

80~200{c/min}(And the filling quantity and so on) |

|

Power |

5.5kw |

7.5kw |

|

Weight |

4000kg |

5800kg |

|

Dimension |

2800x1600x1900mm |

3214x2104x1900mm |

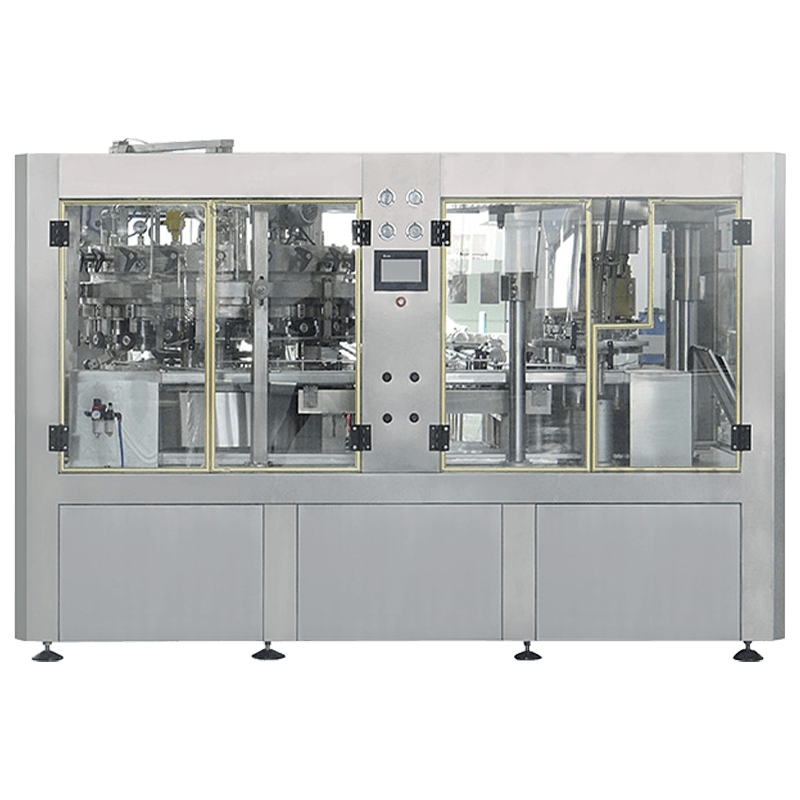

The machine adopts the principle of piston filling. After the empty can is sent to the filling position, the compressed air will enter into the cylinder after passing through the pneumatic triplex parts to turn on the filling valve. Under the action of the cam, the piston will move downwards in the piston-cylinder to carry out filling. After the filling is finished, the filling valve is automatically closed under the action. After it is discharged, the filled can is sent to the sealing machine for sealing by the hook chain that runs synchronously. After the can support mechanism of the seaming machine raise the can supporting disc, the pressing head will press the cap, and the two trolleys will respectively carry out pre-sealing and real sealing of the can under the action of the cam. The sealed can be sent to the can discharging conveyor belt under the action of the can discharging dialing wheel.

The machine adopts PLC, frequency converter, human-machine interface controlling system, having the advanced controlling technologies, such as frequency control, no can no filling and so on. The accurate production rate and quantity will be displayed on the touch-screen via the kinds of sensors on the machine. Moreover, the production rate can be set on the touch screen. The main motor and other electrical equipment are all in a protection state. Meanwhile, all of the malfunctions can be found out easily because they will be displayed on the touch screen. The main electric and pneumatic components of the machine are famous imported brands, and it also can be disposed of according to the client’s requirements.

It is suitable for filling various sauces (such as ketchup, pepper sauce, fruit jam), viscous materials and beverages of high strength or containing pulps or granules, and even rationed filling of pure liquids

Zhejiang Bowei Food Machinery Co., Ltd. is located in Puxi Industrial Park, Putuo District, Zhoushan City which is known as the Oriental Pearl of the Motherland and the Thousand Island City. It faces Mount Putuo across the sea. The company is 12 kilometers away from Putuoshan Airport and there are three flights to and from Shanghai International Airport every day. It is also 100 kilometers away from Ningbo Lishe Airport, so the transportation is very convenient.

The company covers an area of 20 acres. We mainly engaged in designing and manufacturing the filling and sealing machines for packing beverage, cans, milk powder and matching products with the tinplate, aluminum, plastic and paper materials. We have the capacity to manufacture the whole production line to undertake projects such as canned drinks (with or without steam), canned mixed congee and canned ketchup. OEM Custom Thick sauce filling and sealing combination machine Manufacturers, Factory in China.

Through unremitting efforts, our company has obtained international quality certification, ISO quality system certification and CE certification. We also obtained a number of national utility model patents. We serve all customers by our powerful technical strength, effective technical guarantee, flexible business philosophy, professional service, advanced manufacturing technology, excellent product quality and good reputation. We sincerely welcome friends from all walks of life to visit us.

Established

Area

To Putuoshan Airport

Own assets

As OEM Thick sauce filling and sealing combination machine Manufacturers, our company has obtained international quality certification, ISO quality system certification and CE certification. We also obtained a number of national utility model patents.

Filling and sealing machine

Can filling and sealing combination machine

(Beer, Beverage) industrial Filling and sealing combination machine

Thick sauce filling and sealing combination machine

Automatic thick sauce filling machine

(Eight Treasure Congee) Granule Canning Machine

(Corn) pellet canning machine

Automatic sealing machine

800.png?imageView2/2/format/jp2)

(Beer) High speed filling and sealing machine

High-speed sealing machine