2012

Established

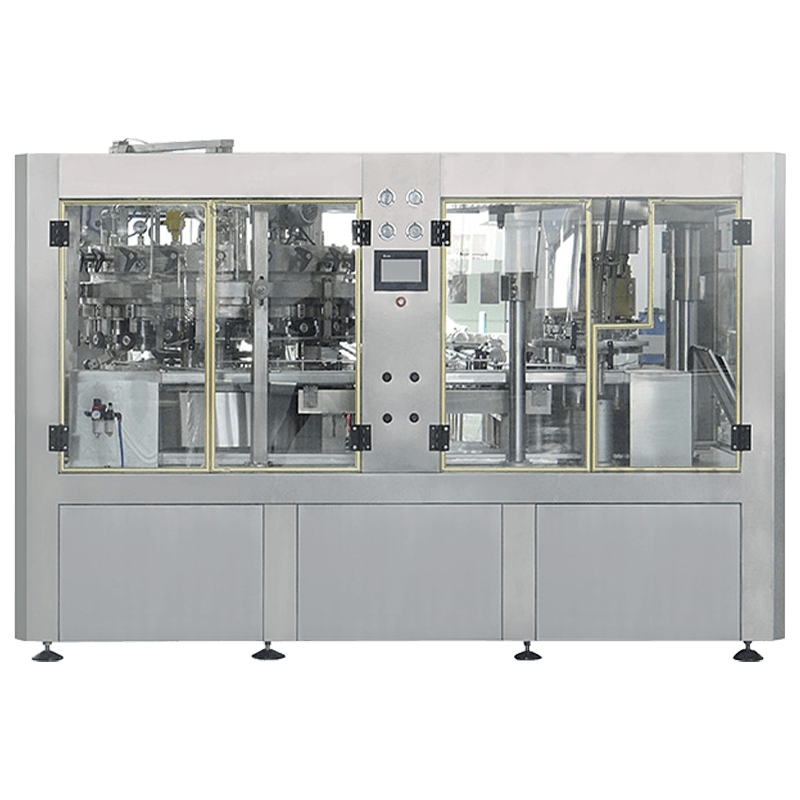

MAIN TECHNICAL PARAMETERS:

|

PRODUCT NAME |

HIGH-SPEED SEALING MACHINE |

|

MODEL |

BWFGJ400 |

|

THE NUMBER OF CAPPING HEAD |

6 |

|

PRODUCTIO CAPACITY |

60~400CANS/MIN |

|

CAN DIAMETER |

Ф52.3~99(SPECIAL SPECIFICATIONS FOR105) |

|

CAN HEIGHT |

39~160MM |

|

POWER |

7.5KW |

|

WEIGHT |

2000KG |

|

DIMENSION |

1600×1200×1900MM |

The machine is advanced pop can filling and seaming machine. After it passes through the dialing wheel, the empty can will enter into the lift tray and rise for sealing. The pressing head presses the can mouth, the sealing wheel carries out pre-sealing and then real sealing. After it is sealed, the can is pushed out by the beating head of the cap beating mechanism and then enters into the can discharging procedure. The main electric components include PLC and proximity switch of Japan Mitsubishi, vacuum sensor, and solenoid valve of South Korea. The overall production speed can be set freely on the touch screen according to requirements.

Compares with the original model, the main advantages are as follows:

①.Compares with the BWFGJ250 old machine, the integral structure of the BWFGJ new machine is more reasonable and beautiful.

②.The machine head diameter of the new seaming machine is obviously large than that of the old one. The new machine is installed with heavy-duty bearings, and the service life of the sealing cam is prolonged, which id increased by over 5 times.

③.The seaming shaft of the new machine adopts the double-shaft structure with a separate primary trolley and secondary trolley so that the feeding volume of the sealing wheels can be respectively adjusted and controlled without influencing the sealing quality due to machining error or wear of the cam.

④. During the sealing, the rotation direction of the new machine is counterclockwise, so that when the sealing is finished the cans will automatically leave the sealing machine according to its rotation direction, which can avoid can blocking and damage to cans

Zhejiang Bowei Food Machinery Co., Ltd. is located in Puxi Industrial Park, Putuo District, Zhoushan City which is known as the Oriental Pearl of the Motherland and the Thousand Island City. It faces Mount Putuo across the sea. The company is 12 kilometers away from Putuoshan Airport and there are three flights to and from Shanghai International Airport every day. It is also 100 kilometers away from Ningbo Lishe Airport, so the transportation is very convenient.

The company covers an area of 20 acres. We mainly engaged in designing and manufacturing the filling and sealing machines for packing beverage, cans, milk powder and matching products with the tinplate, aluminum, plastic and paper materials. We have the capacity to manufacture the whole production line to undertake projects such as canned drinks (with or without steam), canned mixed congee and canned ketchup. OEM Custom High-speed sealing machine Manufacturers, Factory in China.

Through unremitting efforts, our company has obtained international quality certification, ISO quality system certification and CE certification. We also obtained a number of national utility model patents. We serve all customers by our powerful technical strength, effective technical guarantee, flexible business philosophy, professional service, advanced manufacturing technology, excellent product quality and good reputation. We sincerely welcome friends from all walks of life to visit us.

Established

Area

To Putuoshan Airport

Own assets

As OEM High-speed sealing machine Manufacturers, our company has obtained international quality certification, ISO quality system certification and CE certification. We also obtained a number of national utility model patents.

Filling and sealing machine

Can filling and sealing combination machine

(Beer, Beverage) industrial Filling and sealing combination machine

Thick sauce filling and sealing combination machine

Automatic thick sauce filling machine

(Eight Treasure Congee) Granule Canning Machine

(Corn) pellet canning machine

Automatic sealing machine

800.png?imageView2/2/format/jp2)

(Beer) High speed filling and sealing machine

High-speed sealing machine