What are the safety considerations associated with operating a filling and seaming machine?

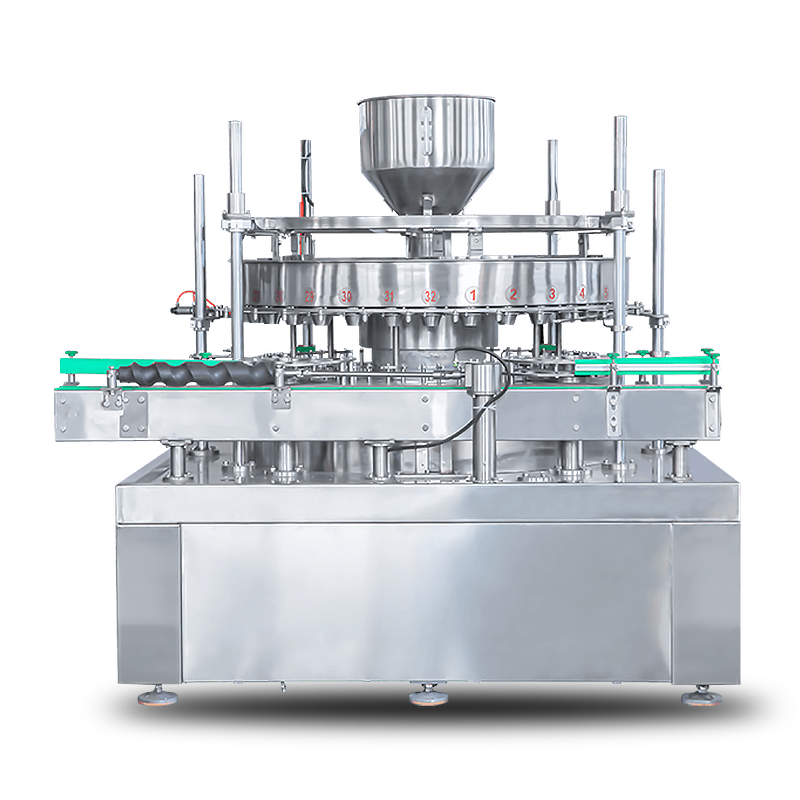

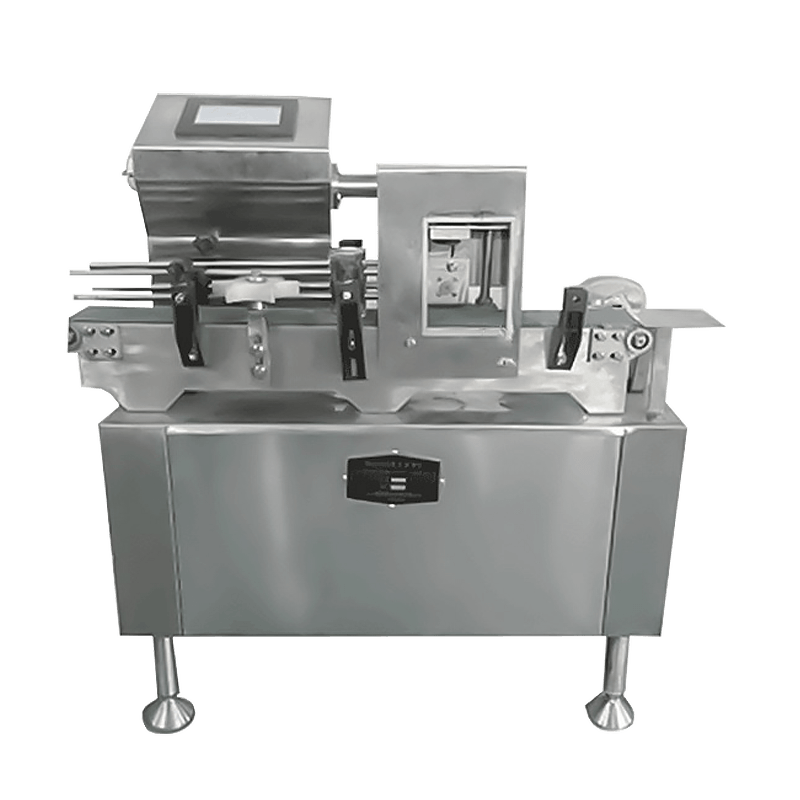

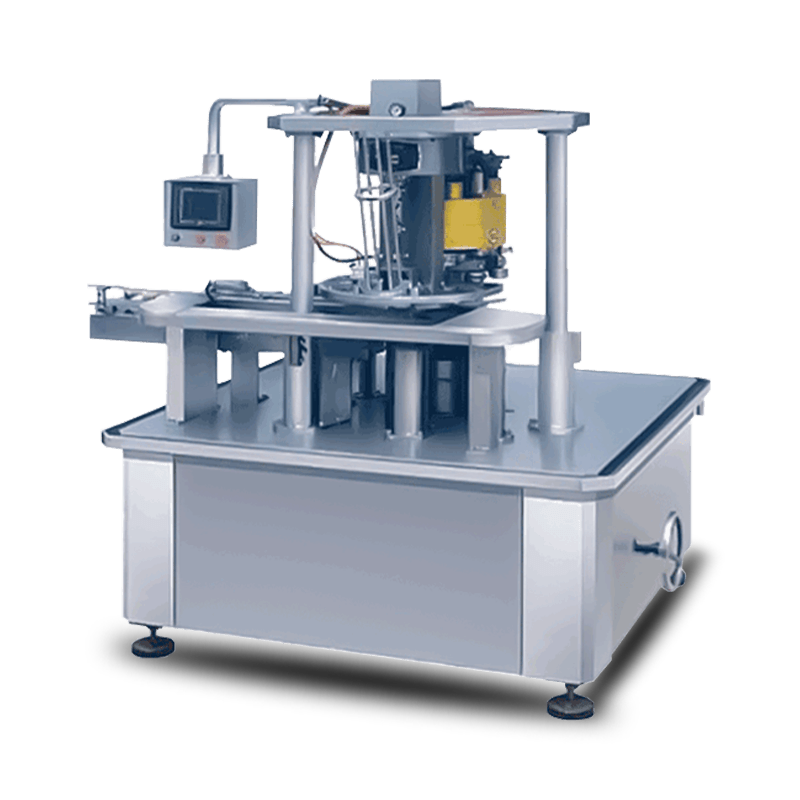

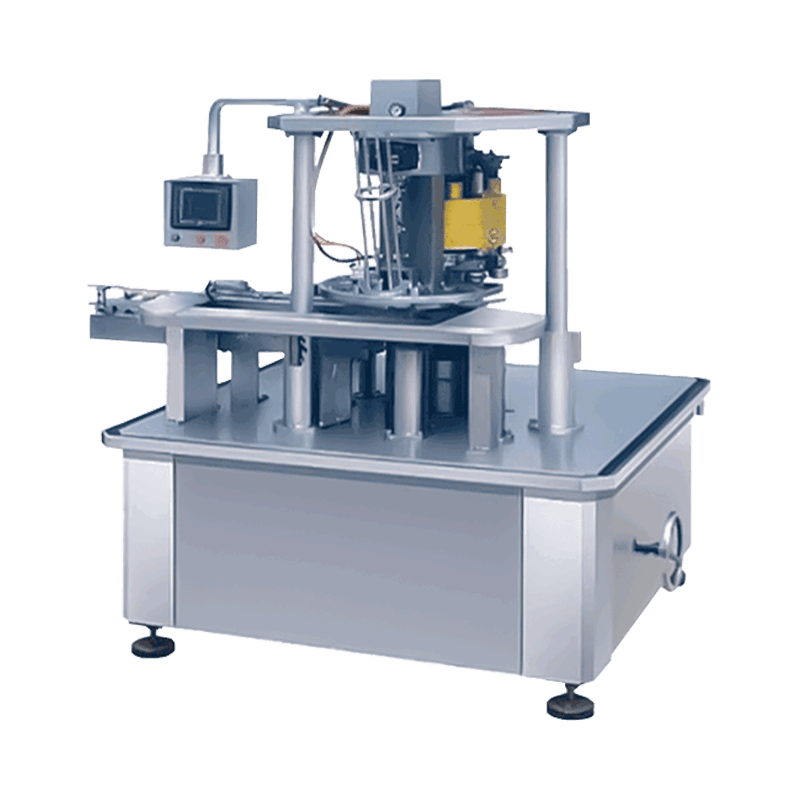

Operating a filling and seaming machine requires strict adherence to safety guidelines to protect both the machine operator and other personnel in the vicinity. Filling and seaming machines are commonly used in industries such as food and beverage, pharmaceuticals, and cosmetics to fill containers (such as cans or bottles) with products and seal them securely. Here are some important safety considerations associated with operating a filling and seaming machine:Operator Training: Ensure that the machine operator receives comprehensive training on how to operate the filling and seaming machine safely. Training should cover machine functions, emergency procedures, and safe operating practices.Read the Manual: Familiarize yourself with the manufacturer's operating manual, safety guidelines, and recommended maintenance procedures. The manual will provide essential information on how to use the machine correctly and safely.Personal Protective Equipment (PPE): Operators should wear appropriate PPE, including safety glasses, gloves, and any other required protective gear, to safeguard against potential hazards like spills, splashes, or moving machine parts.Machine Guards and Safety Features: Ensure that the filling and seaming machine is equipped with proper guards and safety features. These may include emergency stop buttons, safety interlocks, and barriers to prevent access to moving parts during operation.Preventive Maintenance: Regularly inspect and maintain the machine to keep it in optimal working condition. Address any mechanical issues promptly to reduce the risk of accidents or malfunctions.Cleanliness and Hygiene: Maintain a clean and organized work area to prevent contamination of products and reduce the risk of slips and falls.Handling Hazardous Materials: If the filling and seaming process involves hazardous materials, follow appropriate safety protocols for handling, storage, and disposal of these substances.Proper Loading and Unloading: Ensure that containers are correctly positioned and secured on the machine's conveyor system to prevent jams and spills during the filling and seaming process.Monitoring and Supervision: Assign a responsible person to monitor the machine's operation and be prepared to intervene in case of emergencies or malfunctions.Lockout/Tagout Procedures: Implement lockout/tagout procedures when performing maintenance or repair tasks on the machine to prevent accidental startup or movement.Emergency Procedures: Establish clear procedures for dealing with emergencies, such as spills, machine malfunctions, or power failures, and train all personnel on these protocols.Risk Assessment: Conduct a risk assessment to identify potential hazards associated with the specific filling and seaming process and implement appropriate control measures to mitigate risks.Communication: Encourage open communication among machine operators and other personnel regarding safety concerns, issues, and best practices.By implementing these safety considerations and promoting a safety-conscious culture, the risk of accidents and injuries associated with operating a filling and seaming machine can be significantly reduced, ensuring a safe working environment for all involved.

English

English 中文简体

中文简体 中文简体

中文简体

READ MORE

READ MORE