How does automation improve efficiency and productivity in filling and seaming processes?

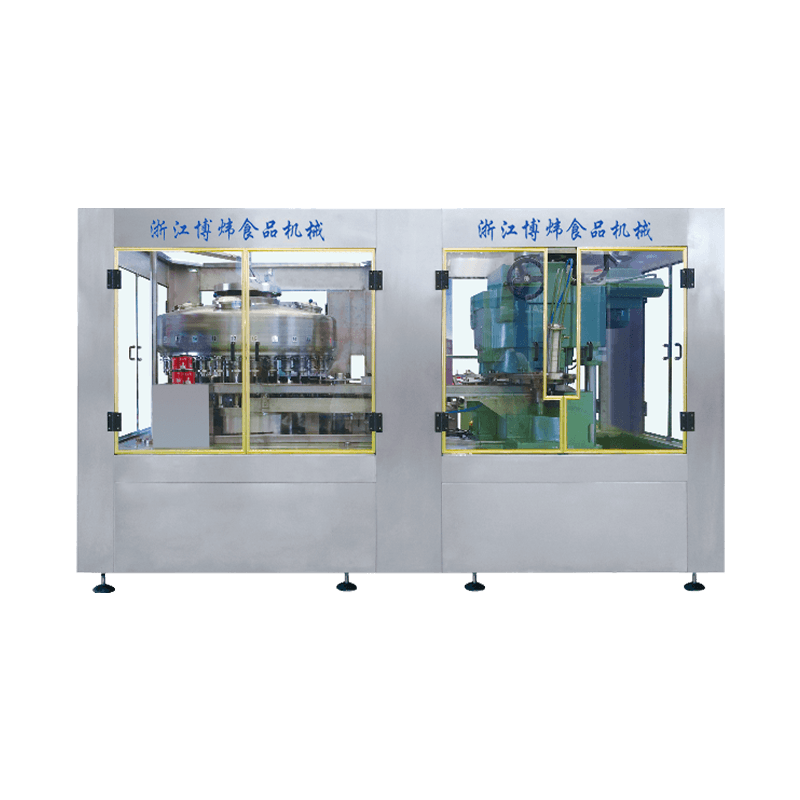

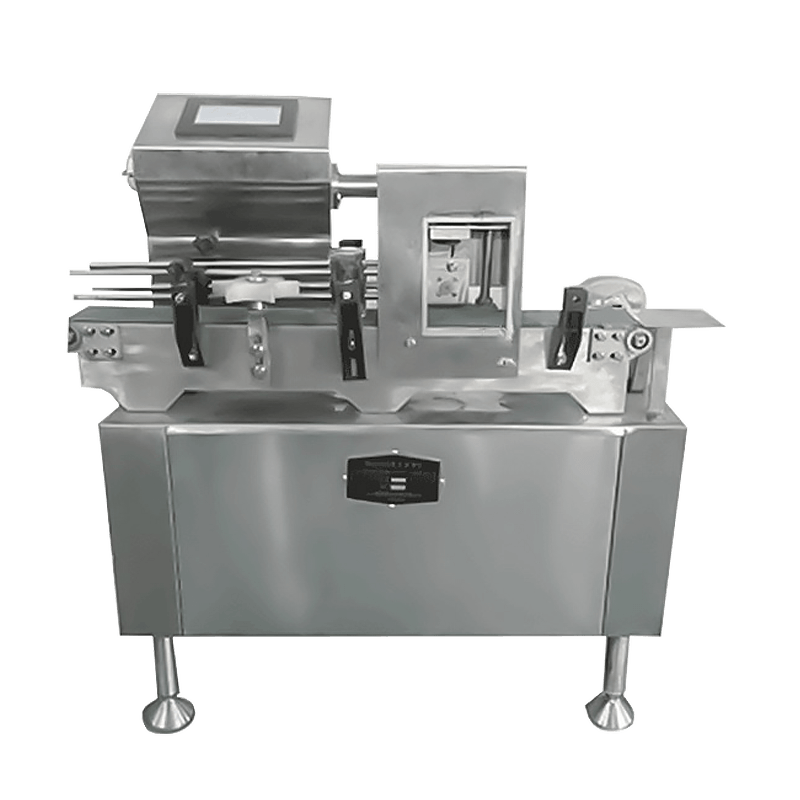

Automation can significantly improve efficiency and productivity in filling and seaming processes in various industries, such as food and beverage, pharmaceuticals, and manufacturing. Here are several ways in which automation contributes to enhanced efficiency and productivity in these processes:Speed and Accuracy: Automated filling and seaming machines can perform tasks at a much higher speed and with greater accuracy than manual labor. This leads to a higher throughput of finished products in a shorter amount of time.Consistency: Automated systems ensure a consistent and uniform product quality. The precision of automation eliminates variations in fill levels, cap placement, and seam integrity that can occur with manual processes, reducing the likelihood of defects and rejects.Reduced Labor Costs: By replacing manual labor with automation, companies can reduce labor costs associated with hiring, training, and managing employees. This cost savings can be substantial in the long term.24/7 Operation: Automated filling and seaming machines can operate continuously, 24 hours a day, seven days a week, without the need for breaks or shifts. This leads to uninterrupted production and increased output.Productivity Metrics: Automation systems often come with monitoring and control capabilities. This allows companies to track and analyze productivity metrics in real-time, identifying bottlenecks and inefficiencies for continuous process improvement.Safety: Some filling and seaming processes can be hazardous for workers, especially when dealing with certain chemicals or high-speed machinery. Automation reduces the risk of accidents and improves overall workplace safety.Reduced Product Loss: Automation systems can minimize product loss due to spillage or improper filling. Precise control ensures that each container is filled accurately, minimizing waste.Flexibility: Many automated filling and seaming machines can be easily reconfigured for different container sizes and product types. This flexibility allows manufacturers to adapt quickly to changing production needs.Quality Control: Automation can include integrated quality control measures, such as vision systems and sensors, which can detect defects and inconsistencies in real-time. This prevents faulty products from entering the market.Inventory Management: Automation systems can be linked to inventory management software, helping companies maintain optimal stock levels and reducing the risk of stockouts or overstock situations.Energy Efficiency: Some modern automated systems are designed with energy-efficient features, such as variable-speed drives and power-saving modes, which can lead to reduced energy consumption and cost savings.Reduced Downtime: Automated systems are less prone to human errors, which can lead to reduced downtime caused by maintenance or troubleshooting.In summary, automation in filling and seaming processes offers numerous advantages, including increased speed, consistency, and accuracy, reduced labor costs, enhanced safety, and improved product quality. These benefits collectively lead to greater efficiency and productivity, making automation a valuable investment for many manufacturing and packaging operations.

English

English 中文简体

中文简体 中文简体

中文简体

READ MORE

READ MORE